Cellix Ltd with Trinity College Dublin (TCD) and University of Galway (UG).

The Gene Transfection Cell Analysis and Sorting Platform (GTCASP) project sought to develop a fully automated, closed loop system for cell manufacturing for gene therapies.

GTCASP-DTIF launch event

From L-R: Vivienne Williams (CEO, Cellix Ltd), Dr Larry Bacon (Clinical Lead of the designated national centre for CAR T-cell therapy), Dr Orlaigh Quinn ((former) Secretary General of DBEI), Dmitry Kashanin (CTO, Cellix Ltd), Dr Birgit Nelsen-Salz (Lonza), Stephen Creaner (Executive Director of Enterprise Ireland Food, Industrial, Life Sciences and Innovation) and Prof Frank Barry (Cellular Therapy, UG (formerly NUIG)) February 2020

The Disruptive Technologies Innovation Fund (DTIF) is a €500 million challenge-based fund established under Project Ireland 2040.

The fund seeks to invest in the research, development and deployment of disruptive technologies on a commercial basis. It will drive collaboration between Ireland’s world-class research base and industry as well as facilitating enterprises to compete directly for funding in support of the development and adoption of these technologies.

“We can’t recommend this grant enough”

Vivienne Williams CEO, Cellix Limited

The challenge

Gene and cell therapy is a groundbreaking technology in medicine aimed at treating diseases by modifying genetic or cellular material. It has the potential to eradicate infectious diseases such as malaria and yellow fever and curing inherited conditions such as cystic fibrosis and cancer. Current techniques include replacing an abnormal or a non-functional gene with a normal gene. Although these techniques show exciting promise, the manufacturing of cells on a mass production scale is an extremely long and complex process.

Figure 1 - The Inish Analyser (Source: wearecellix.com)

Cellix’s first product, the lnish Analyser (Figure 1), is a microfluidic impedance-based flow cytometer for cell counting and analyses efficiencies. This represents a disruptive advantage over traditional methods. This technology not only aims to revolutionise gene and cell therapies but is also applicable to sectors like Food and Drink, Agri-biotech, and synthetic biology.

Project inputs

During the course of the project, Cellix supported seven jobs, with two research positions created in UG and three in TCD. Two of the staff in TCD found positions in Cellix Ltd once the project was complete. Cellix’s growth is primarily contributed to the €3 million in funding awarded to the project under Call 1 of the Disruptive Technologies Innovation Fund. Additionally, Cellix qualified for prefinance, which was a crucial step in the project’s early success, allowing the company to begin allocating staff and procuring materials shortly after award announcement.

Figure 2 - The REMEDI Centre at UG (Source: wearecellix.com)

For the production of cellular and gene therapies and to ensure that all materials used in the project complied to FDA standards, the project utilised a clean room facility which was operated within The National Stem Cell Manufacturing Facility, and managed and controlled by UG-REMEDI (pictured above). This strategy mitigated any potential risks associated with increased regulation on specific materials vital to the development of the project.

Cellix’s microfluidic and impedance analysis technology has gained significant interest in multiple sectors. In the United States, its application can be tailored to solutions in Agri-biotech and the food and beverage industry as a rapid, low-cost device for the analysis of yeast and bacteria in beer.

The problem

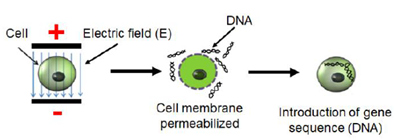

A significant initiative of the project was to move away from the most common method of gene editing, known as transduction. This involves using a virus to deliver DNA into a cell. This method can sometimes result in a severe immune response in patients which has resulted in deaths to occur in some clinical trials. The move is therefore to develop a method of delivering DNA into a cell using a non-viral method, this is known as transfection. This method applies an electrical field that increases the permeability of a cell membrane, allowing DNA to be introduced into a cell (Figure 1). This method is increasingly popular and is particularly useful when using larger gene edits and CRISPR techniques.

Figure 4 - Transfection introducing DNA into a cell (Source: wearecellix.com)

However, there are still challenges with traditional bulk transfection methods. T-Cells, B-Cells and stem cells are notoriously difficult to transfect. This project seeks to address these challenges by implementing an on-chip transfection method that can be tailored to each individual cell.

The Gene Transfection Cell Analysis and Sorting Platform (GTCASP) project sought to develop a fully automated, 'on chip' closed loop system for cell manufacturing for gene therapies. To test and validate this technology, Cellix worked closely with TCD-Med and University of Galway in T-Cell and stem cell biology. Comprising of a microfluidic chip through which cells from patients or donors are characterized, sorted and subsequently genetically modified and sorted again, the GTCASP system was achieved but in a modular format meaning independent modules could be integrated to a workflow.

“The fund is a powerful and progressive instrument for advancing innovation in Ireland”

– Prof Frank Barry, University of Galway

The solution

This project sought to develop a fully automated, 'on chip' closed loop system for cell manufacturing for gene therapies. A microfluidic chip allowed cells from patients and donors to be characterised, sorted and subsequently genetically modified. This automation will ensure that multistep functions can be processed faster and in a high throughout manner while remaining sterile.

All eight work packages are complete. Essentially, each work package can be attributed to the development of following three modules: Cell sorting, Cell Analysis and Gene transfection. Experts from TCD and UG specialising in T-Cell and stem cell biology provided input which was crucial to the development of the project.

One major contribution to the Inish Analyser was its adaption by UG for use in stem cell research. This allowed for cell transfection with biologically relevant genes. Figure 5 below outlines the steps to initiate one of the Inish Analyser functions – cell counting and cell viability.

Figure 5: Cell counting and cell viability using the Inish Analyser (Source: wearecellix.com)

More challenges

Pandemic related restrictions preventing access to laboratories and supply chains, severely impacted the development of the project. This made the procurement of critical electronic components and staff challenging, particularly in the prototyping and the design processes. Due to this uncertain economic environment, the consortium sought a no cost extension of 12 months.

From a technical perspective, as a result of the global electronic component shortage, the off-chip sorting setup had to be redesigned to interface with a replacement component when the procurement of the original component was not possible.

Overall, the project made good technical progress throughout, with a well-managed project coordinator.

Outcomes

- Positive feedback from customers is driving the commercialisation effort.

- One patent has been filed with the European Patents Office titled 'A method of determining the transfection status of plurality of cells'.

- Significant demand for a fully automated closed system that will ensure sterility and efficient transfection for cell manufacturing.

- Potential for future collaborative research.

Lessons learned

- Collaborative contributions guided the project in new directions and gave all parties a deeper understanding of gene and cell biology.

- All partners adapted well to external pressures.

- Free sharing of knowledge, optimum learnings and an actively engaged workforce was crucial.

- Feedback from Call 1 applicants contributed to the update of EI and department's decision making processes.

Watch on YouTube: we are cellix - YouTube